This is a script done last year during spring break, first posted on Grasshopper forum and modified once. The reason for doing this is a manifold (I mean multiple reasons),

- Many existing scripts on the forum takes in a Surface and offset, no script takes an closed polysurface for this operation.

- I’m learning GH in that peirod, and I think it would be a good exercise for me.

- I was making very enormous site models in Year 1, and I have a believe that making those stupid site models should not waste my life.

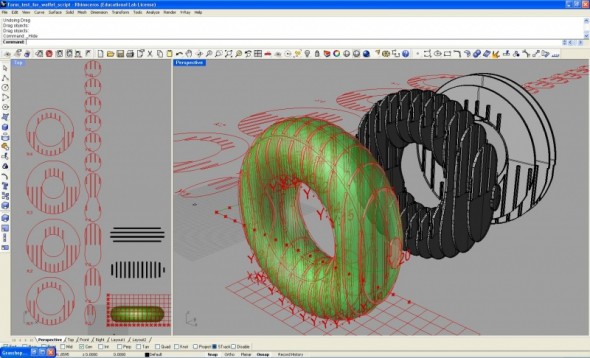

This script is aim to take in a closed polysurface (solid in that sense) (by a referenced Brep) for generating a laser cutting waffle.

It can handle hollow forms, cantilevering masses and can generally take more complex geometry then the usual section plane-section curve algorithm. This is because of an operation which determines the middle point for notch/slot to happen, instead of the usual fixed height notching.

The script itself is pretty sophisicated as it incoperated multiple fine-tunes.

- Rhino Boolean is famous for failing, this will happen especially if you have a poorly built polysurface or un-closed polysurface (which will definitely fail

- Normal boolean failure because of surfaces just touching each other can be ovecome by moving the surfaces by a very small amount (as little as 1/mil part) So change the Boolean Fail Slider if things go wrong.

I have to declare some design intension:

- It uses a global coordinate grid to determine cutting plates location, starting from zero-zero, cutting to the positive X and positive Y. This allows two adjoining geometry to be calculated and cut separately. (some inconvince is: you need to place your model at the upper right hand quadrent of zero-zero) I made it like this to allow flexibility to nudge the model location while the section planes remain unchanged. You could also bake multiple large solids and that the section planes match

- If you have a surface to waffle, you can always extrude it or offset it to create a brep.

- I called the rectangular stick that boolean out the slot as ‘fries’ in case you dont know what I mean in the script.

The basic operation is like this:

- Locate your geometry near the zero-zero. Do it in the top view, and keep everything on the upper right quardrent of  zero-zero.

- Adjust the X and Y spacing and number of sections. So that the cutting planes intersect the whole geometry. (Units are all ‘units’ in Rhino)

- Reference the Brep. the script should calculate for a while.

- You can adjust the material thickness.

- The X and Y layout spacing and offset helps lay out the cut files.

- Cut you file.

- I would appreciate if you post your result, successful or not to the GH forum (this thread) to share.

This is the definition: